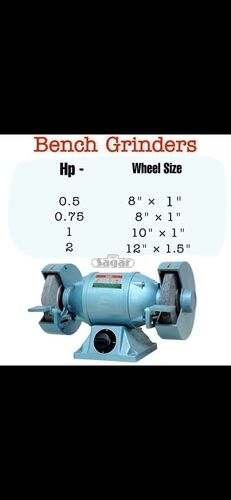

Bench Grinders

Product Details:

Bench Grinders Price And Quantity

- 7000 INR/Unit

- 1 Unit

- 7000.00 - 11000.00 INR/Unit

Bench Grinders Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 100 Unit Per Month

- 5 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

Sagar Machine Tools

We are Leading Manufacturer of Bench Grinders A bench grinder is a versatile and widely used tool in workshops, garages, and metalworking environments. It is a stationary machine mounted on a bench or pedestal, equipped with abrasive wheels for various grinding, sharpening, and shaping tasks. Bench grinders are commonly used to sharpen tools, remove rust or burrs from metal, and perform other tasks that involve grinding or shaping materials.

Here are key features and aspects of bench grinders:

Motor and Power: Bench grinders are typically powered by an electric motor. The power of the motor can vary, and higher horsepower allows for more efficient grinding and handling larger workpieces.

Grinding Wheels: Bench grinders are equipped with one or more grinding wheels. These wheels are typically made of abrasive materials like aluminum oxide or silicon carbide. The wheels come in different grit sizes for various applications, ranging from coarse to fine.

Wheel Guards: For safety reasons, bench grinders are fitted with wheel guards that cover the grinding wheels. These guards protect the user from sparks, debris, and potential wheel breakage.

Tool Rests: Tool rests are adjustable platforms that support the workpiece during grinding. They help maintain a consistent angle and distance between the grinding wheel and the workpiece, aiding in precision.

Spark Deflectors: Spark deflectors are additional safety features that help direct sparks away from the user and the surrounding area. Adjustable Speed: Some bench grinders come with adjustable speed settings, allowing users to control the grinding speed based on the specific task or material. Coolant Tray: Some industrial bench grinders include a coolant tray to prevent the workpiece and grinding wheel from overheating during prolonged use. Coolant can be added to the tray to lubricate and cool the grinding process.

Applications: Bench grinders are used for a variety of tasks, including sharpening tools (such as chisels, drill bits, and knives), removing burrs or rust from metal, and shaping or polishing metal surfaces. Safety Considerations: Safety is crucial when using a bench grinder. Users should wear safety glasses to protect their eyes from debris and sparks. Additionally, proper safety precautions, such as using the wheel guards and following manufacturer guidelines, should be observed. Maintenance: Regular maintenance, such as checking for wheel wear and ensuring the tool rests are properly adjusted, is important for the safe and effective operation of a bench grinder. Bench grinders are available in various sizes and configurations, and the choice of a specific model depends on the intended applications and the user's requirements. They are widely used in metalworking, woodworking, and general maintenance tasks.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS