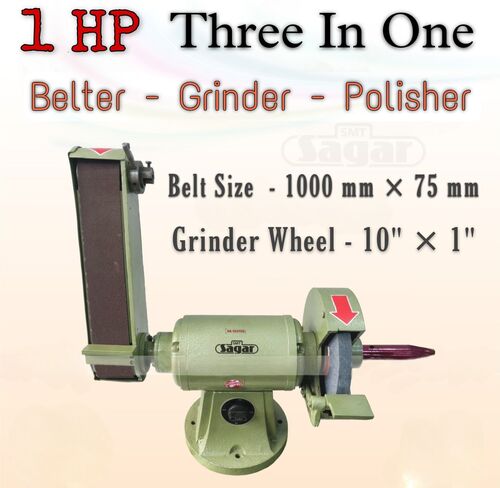

Three In One Belter Grinder Polisher

Product Details:

Three In One Belter Grinder Polisher Price And Quantity

- 1 Unit

- 17000 INR/Unit

Three In One Belter Grinder Polisher Trade Information

- Cash Advance (CA) Cash in Advance (CID)

- 10 Unit Per Month

- 1 Week

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India Central India West India North India East India Gujarat Karnataka Kerala Lakshadweep Mizoram Meghalaya Manipur Andhra Pradesh Bihar Chandigarh Daman and Diu Goa Jharkhand Odisha Punjab Assam Delhi Dadra and Nagar Haveli Andaman and Nicobar Islands Arunachal Pradesh Chhattisgarh Haryana Himachal Pradesh Jammu and Kashmir Madhya Pradesh Maharashtra Nagaland Rajasthan Sikkim Tamil Nadu Telangana Tripura Pondicherry Uttar Pradesh Uttarakhand West Bengal

Product Description

Three in One Belt Grinder Polisher

An abrasive belt grinding machine is a tool that uses abrasive belts to grind and finish workpieces. These machines come in various configurations and designs, depending on the specific application and the type of workpiece being processed.

Here are some common features and components found in abrasive belt grinding machines:

Belt Configuration: The machine features a continuous loop of abrasive belt(s), typically made of coated abrasives such as aluminum oxide, silicon carbide, or other abrasive materials.

Drive System: A motor provides the power to rotate the pulleys that drive the abrasive belt. The drive system must be capable of maintaining the desired belt speed for effective grinding.

Belt Tensioning Mechanism: To ensure proper performance, abrasive belts need to be tensioned correctly. Machines usually include a mechanism for adjusting and maintaining the tension of the abrasive belt.

Tracking Mechanism: A tracking system is essential to keep the abrasive belt centered on the machine. This helps prevent the belt from wandering off the pulleys, ensuring consistent and accurate grinding.

Worktable or Workrest: The workpiece is typically placed on a worktable or workrest during grinding. The worktable can be adjustable to accommodate different workpiece sizes and shapes.

Adjustable Tool Rests: Tool rests provide support for the workpiece and can be adjusted to achieve the desired grinding angle and position.

Coolant System: In some applications, especially in metalworking, coolant systems may be integrated into the machine to cool the workpiece and abrasive belt, reducing heat and preventing overheating.

Dust Extraction System: Abrasive grinding generates dust and debris. Many machines are equipped with a dust extraction system to remove these particles, improving visibility, air quality, and safety in the workspace.

Safety Features: Safety is a priority when using abrasive belt grinding machines. Safety features may include emergency stop buttons, machine guarding, and protective covers to prevent operator injuries.

ariable Speed Control: Some machines offer variable speed control, allowing operators to adjust the belt speed based on the specific requirements of the application.

Abrasive Belt Changing System: Depending on the design, the machine may feature a quick and convenient system for changing abrasive belts. Abrasive belt grinding machines are used in various industries, including metalworking, woodworking, and manufacturing, for tasks such as deburring, surface finishing, and material removal. The specific features and capabilities of these machines can vary, so the choice of a particular machine depends on the application requirements and the type of workpiece being processed.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS