Industrial Stapler Machine

Product Details:

Industrial Stapler Machine Price And Quantity

- 6500 INR/Unit

- 1 Unit

Industrial Stapler Machine Trade Information

- 10 Unit Per Month

- 5 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

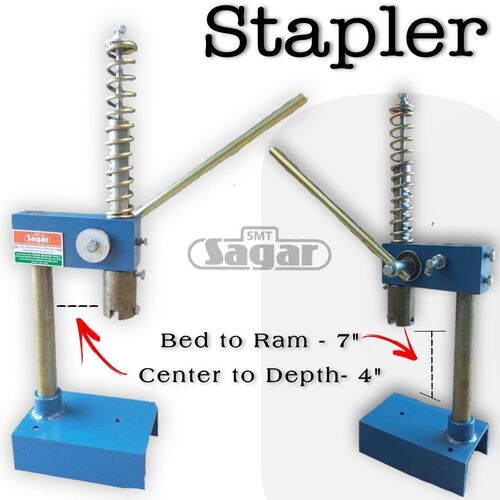

Industrial Stapler

An industrial stapler machine, also known as a stapling machine or stapler, is a piece of equipment designed for efficiently fastening materials together using staples. These machines are used in various industries, including packaging, bookbinding, upholstery, and manufacturing, to streamline the stapling process and provide a reliable and consistent way of joining materials. Here are some key features and aspects of industrial stapler machines:

Types of Industrial Staplers:

Pneumatic Staplers: Powered by compressed air, pneumatic staplers are suitable for high-speed stapling applications and are commonly used in manufacturing and packaging.

Electric Staplers: These staplers are powered by electricity and are often used for moderate-speed stapling tasks. They are suitable for applications where compressed air is not readily available.

Manual Staplers: While not as common in industrial settings, manual staplers are still used for certain applications. They are hand-operated and suitable for lower-volume stapling tasks. Staple Types and Sizes: Industrial staplers can accommodate a variety of staple types and sizes, depending on the specific requirements of the application. Common staple types include flat wire, round wire, and crown staples.

Capacity: Industrial staplers come in various sizes and capacities, ranging from smaller machines suitable for light-duty applications to heavy-duty models capable of handling large volumes of stapling.

Adjustability: Many industrial staplers offer adjustable features, such as depth control and staple leg length adjustments. These features allow users to customize the stapling process based on the materials being joined. Speed and Automation: In industrial settings, stapling machines are often designed for high-speed and automated operation. Some machines can staple a large number of sheets or products in a short amount of time, contributing to increased efficiency in production lines.

Applications: Industrial staplers are used in a wide range of applications, including: Packaging: Closing boxes and cartons. Bookbinding: Binding books and printed materials. Upholstery: Attaching fabric to furniture frames. Manufacturing: Joining various materials in the assembly process. Safety Features: Depending on the model, industrial staplers may include safety features such as guards and shields to protect operators from injury during operation.

Maintenance: Regular maintenance, such as cleaning and lubrication, is essential to ensure the reliable and smooth operation of industrial stapler machines. It's important to select an industrial stapler that aligns with the specific requirements of the intended application. Considerations such as stapling capacity, speed, and staple compatibility should be taken into account when choosing the appropriate stapler for a particular industrial task.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS